Weaving – warp let-off and fabric take-up motions

Warp let-off system has a frequency converter, which is intended for letting off from warp beam or feeding unit. The drive is mounted either on the weaving machine or on a frame positioned behind the weaving machine. The let-off starts with a machine running signal; the speed of the let-off motor is controlled by a proximity switch mounted on the whip roller system and an internal speed memory. An alarm signal switches the weaving machine off in case of over tightened warp or any other error.

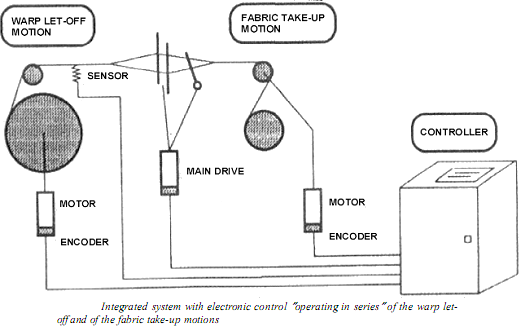

By now all modern weaving machines use integrated electronic systems which are operated by the drive and control unit of the machine. The warp beam and the take-up motions are driven by high precision servomotors equipped with a speed reducer, connected with the machine’s PLC through an encoder (a kind of electronic goniometer) and controlled through a closed adjustment ring. This ensures the synchronization of the weaving machine with the let-off and take-up motions (operating in series): practically the controller can know at any moment the exact position of the various devices.

Batik designs – How to make Batik designs

What is Batik? How to manufacture Batik designs? Origin and details.

A position sensor or a load cell signals at any moment the tension operating on the back rest roller and permits to adjust the let-off speed so that the tension remains absolutely constant from the start to the end of the weaving cycle. Furthermore, the positions of the take-up and let-off motions during the critical starting phases can be adjusted to the running behavior of the material in progress, in order to avoid stripes on the fabric. Also, the weft density can be varied without limitations during weaving and it is also possible to modify the warp tension by means of a simple keying in.