Sewing Needles

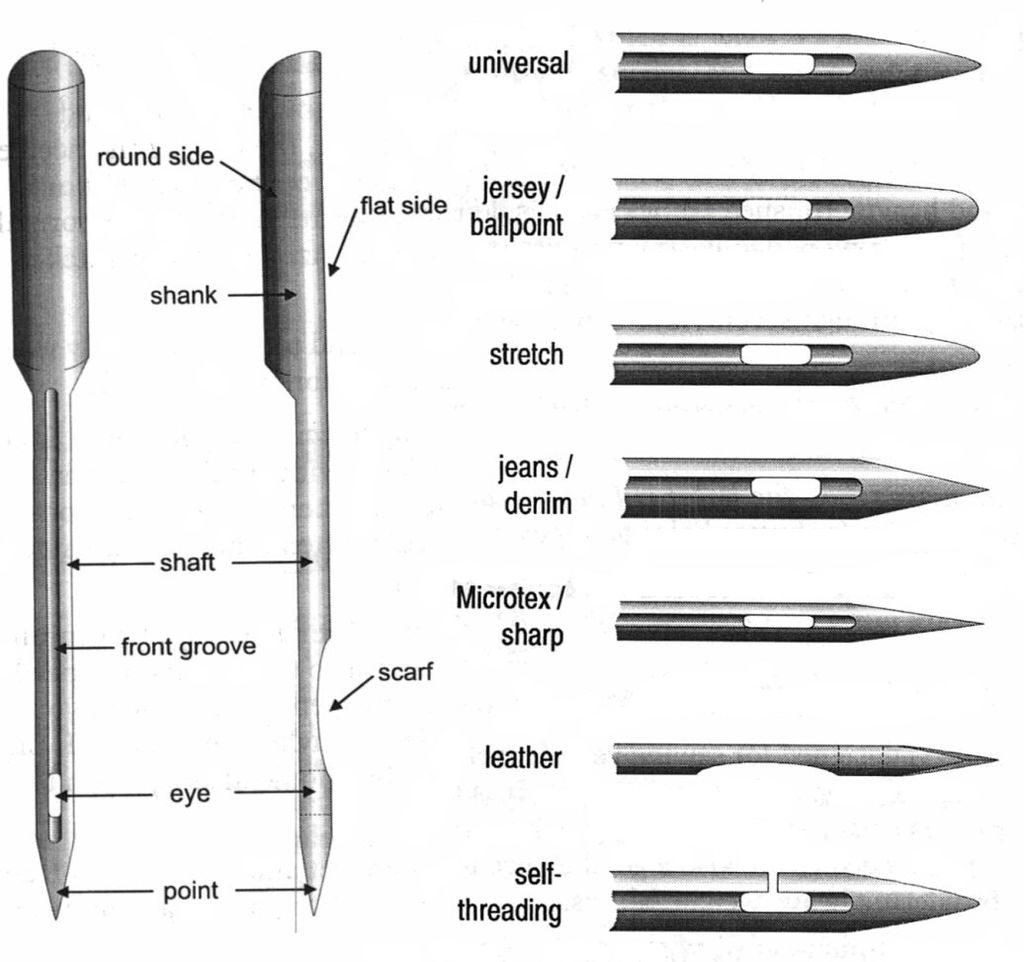

A sewing needle is a long slender tool with a pointed tip. The needle must be able to penetrate the material being sewn, by pushing the yarns aside according to the application, without damaging it. The various parts of the needle are: The shank, The shoulder, The blade, Long Groove, Short Groove, The eye, The point and the Tip.

Sewing Needle

A sewing needle is a long slender tool with a pointed tip. The needle must be able to penetrate the material being sewn, by pushing the yarns aside according to the application, without damaging it. Modern needles are manufactured from high carbon steel wire, nickel or gold plated for corrosion resistance.

Needle Points

Needles are manufactured with a wide variety of needle points appropriate for the different properties of materials which have to be sewn. The needlepoint can be located either centrally or eccentrically. There are two basic classes of points:

- Round points

- Cutting points

Slim Set Point Needles – can penetrate the yarns of the material being sewn through its sharp point and is ideal for all woven fabrics because it helps to produce an even stitch and causes a minimum of fabric puckering. They are used for Blind stitches and for fine, densely woven fabrics. These points are not suitable for knitted fabrics.

Set Cloth Point – needles are slightly rounded to displace yarns of the material being sewn without damaging them. This is most commonly used point.

Heavy Set Point – needles are strongly blunted. These are used for button sewing machines.

Ball Points – Light Ball Point is used for sensitive fabrics such as knits, to prevent damage to the loops. This is crucial for maintaining the fabric’s elasticity. Medium ballpoint and heavy ballpoint are used for fabrics containing stretchable yarns. While sewing the threads are displaced not pierced. The needle pushes between the fabric yarns rather than “cutting rough” the yards.

Cutting Points – are used for sewing leather, coated or laminated fabrics. These are classified and named according to the position of the cutting edge and its shape. The shapes are named with regard to the form of the cutting edge for example spear point, triangular point, diamond point etc. The shape of this needle will create a slit (rather than a large hole) through which the thread will pass.

Needle sizes

Suitable sewing needle type is one of the most important parameters for ensuring the effective and fault free sewing process it will depend on the characteristics of the needle type, needle point, needle fineness, fabric material, the size of sewing thread, the seam type and stitch type.

It is important to use correct needle size for the type of fabric being used. The metric size “Nm” of a needle defines the diameter of the blade (in 1/100 mm) at a point just above the scarf. Fine needles are around Nm 70, medium needles abound Nm80-Nm90 while thicker needles are around Nm100.

The convention for sizing is that the length and thickness of a needle increase as the size number decreases. Delicate fabrics such as silk, chiffon, voile, fine lace and organdie would need a fine “size 9” needle. Lightweight fabrics such as synthetic sheers, taffeta, velvet, stretch fabric and tricot would need a “size 11” needle.

Medium weight fabrics such as poplin, linen, chambray, wool crepe, flannel, knits, jersey, wool, and satin would need an S “size 14” needle. Medium-heavy weight fabrics such as sailcloth, gabardine and tweed fabrics would need a “size 14-16” needle.

Heavy fabrics such as denim, upholstery and canvas fabrics would need a “size 16-18” needle. Most readily available machine needles are sized from 9 to 18. The smaller the number, finer the needle.

Good Practices

- Skip stitches are caused by seam cross sections and thick material parts

- Needle Breakage is due to high penetration forces and strong needle deflection

- Needlepoint damage is generally caused due to poor adjustment with looper causing contact with a hardened looper

- Thread breakage is caused by poor loop formation and insufficient space between thread and needle for picking up by looper

- Use Threading Air Needle for faster threading the needles to avoid wasting time

- Advantages of using correct needle can give straight un-staggered seams less skip stitch problems, fabric damage, less puckering, less needle breakage and higher productivity, optimum protection of Hook point, reduced machine load, reduced thread loss, and reduced production cost.

Trouble Shooting

Seam Puckering in Stretchable fabrics

- Use the smallest size of the needle and smallest thread size

- Use a smaller ball Point needle

- Use minimum pressure on the presser foot

- The tension of needle thread and bobbin or looper thread must be minimal

- Use feed dog with finer teeth

- Do not use bigger SPI (stitch per inch)

- Check needle for wear or damage at point area. Stitch skipping and thread breakage while sewing synthetic fabrics.

- Always use special finish needles with a special coating to reduce friction and overheating

- Decrease needle temperature by using special lubricants or pre-lubricated sewing threads for smoothness and reduced friction

- By cooling needles using a stream of air through the blower

- By reducing revolution of sewing machine causing lower generation of heat on a sewing needle.

Basic Features of Sewing Needle

- Shanks with a circular section

- Shanks with a flat side which serves to locate the needle in a specific position in the needle bar

- Shank thickness is maintained all the way down to needle blade. These kinds are used in specialty needles.

Blade of needle runs from the end of shoulder to the beginning of the eye. Blade increases in thickness from eye to shoulder to increase stiffness. Curved blade needles are used for Blind stitch machines.

The groove is the threading side of the needle. Its function is to guide the thread while forming the stitch and to protect it against excessive friction.

The eye is the hole before needlepoint for sewing thread. The shape of the eye is always extended in its length as the needle thread has to pass diagonally through the needle in the length direction.